What kind of steel is for stainless steel?

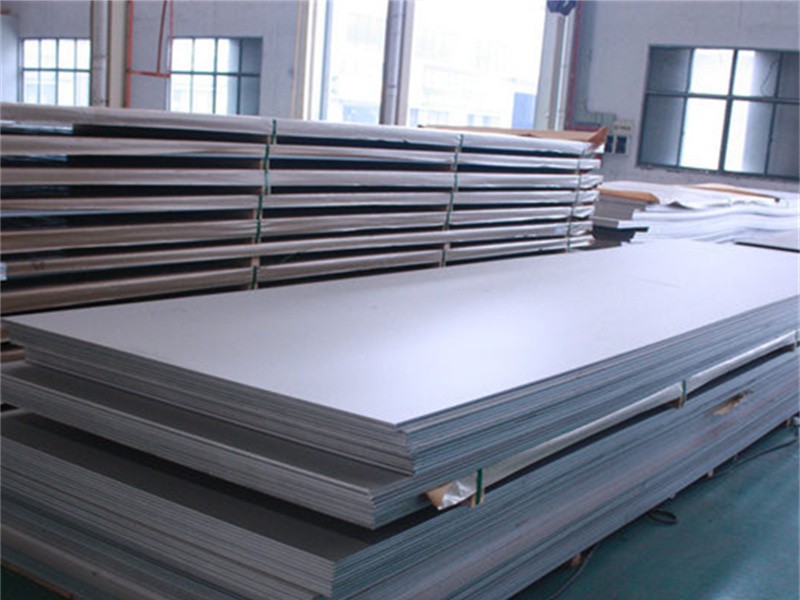

I. Stainless steel is a kind of steel, steel refers to the amount of carbon (C) below 2% is called steel, more than 2% is iron. What kind of steel is stainless steel?

Stainless steel is a kind of steel, steel refers to the amount of carbon (C) below 2% is called steel, more than 2% is iron. Steel in the smelting process to add chromium (Cr), nickel (Ni), manganese (Mn), silicon (Si), titanium (Ti), molybdenum (Mo) and other alloy elements to improve the performance of steel corrosion resistance (that is, no rust) is what we often say stainless steel. Steel in the smelting process to add chromium (Cr), nickel (Ni), manganese (Mn), silicon (Si), titanium (Ti), molybdenum (Mo) and other alloy elements to improve the performance of steel corrosion resistance (that is, no rust) is what we often say stainless steel.

“Steel” and “iron” is what, what characteristics, and what relationship, we usually say 304, 304L, 316, 316L is how to come, what is the difference between each other?

Steel: Material with iron as the main element, generally less than 2% carbon, and containing other elements. — GB/T 13304-91 “Steel Classification”

Iron: A metallic element, atomic number 26. Iron material has strong ferromagnetism, and has good plasticity and thermal conductivity.

Stainless steel: resistant to air, steam, water and other weak corrosive medium or stainless steel. Usually used for steel 304, 304L, 316, 316L, is austenitic stainless steel 300 series steel.

II. why stainless steel has different steel numbers?

Stainless steel in the smelting process, due to the addition of alloying elements of different varieties, different varieties of different amounts. Its characteristics are also different, in order to distinguish the crown on the different steel numbers, the following is common decorative stainless steel with different steel numbers “alloying element” content table for reference only:

304 stainless steel is the most common steel, as a kind of widely used steel, has good corrosion resistance, heat resistance, low temperature strength and mechanical characteristics; Stamping, bending and other hot processing good, no heat treatment hardening phenomenon (no magnetism, then use the temperature -196℃ ~ 800℃).

Auto parts (windshield wiper, muffler, molding products)

Medical equipment, building materials, chemicals, food industry, agriculture, Marine components

Post time: Feb-09-2023