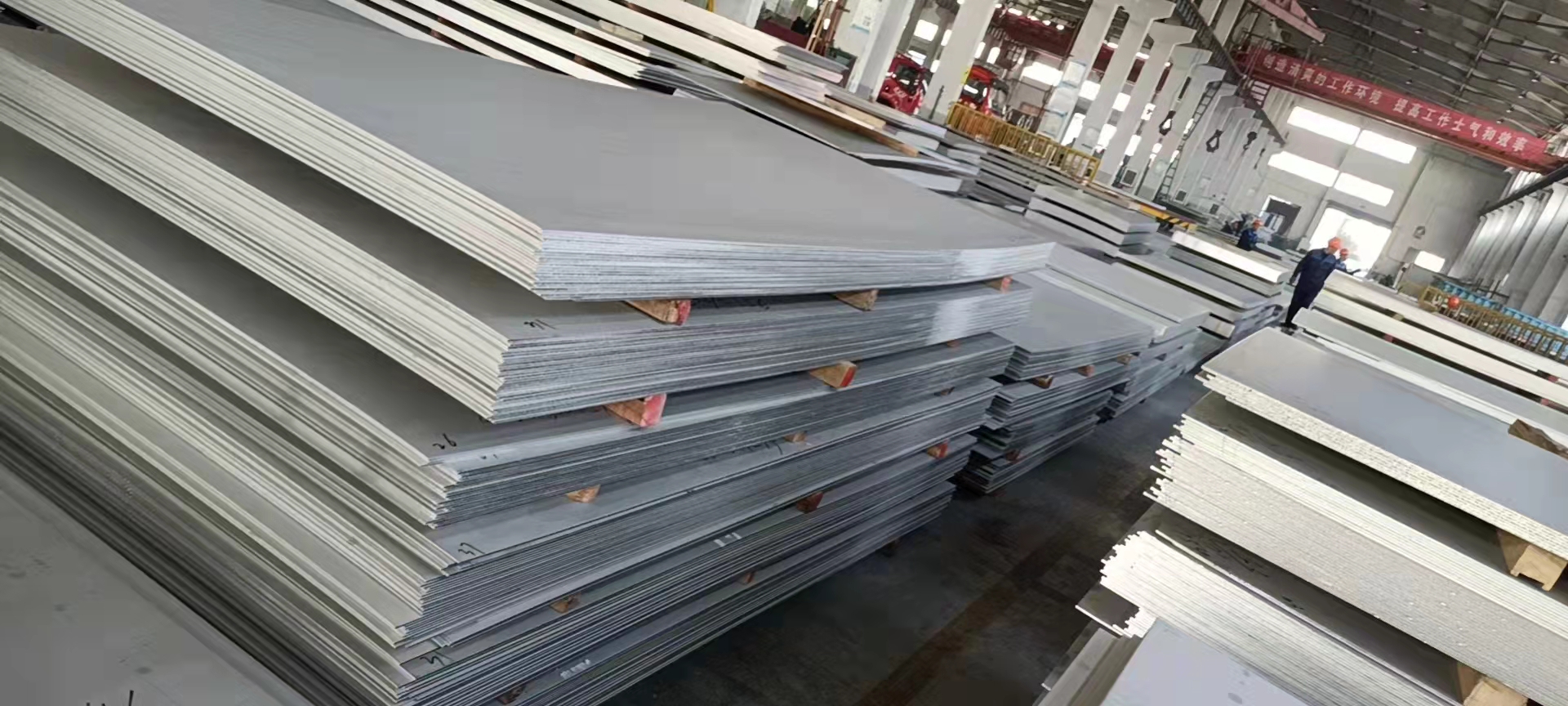

In the first half of April, China Baowu Baosteel Co., LTD. (hereinafter referred to as Baosteel) successfully completed the normal production plan, the effective operation rate of important operation lines in Baoshan Base reached 94.69%, the sales volume of non-oriented silicon steel, Baosteel’s strategic product, doubled year-on-year, and the monthly production of seamless steel tube heat treatment line reached the highest record in 9 years… Behind each figure, benefit from a series of measures of Baosteel shares.

The iron and steel industry is an important basic industry of the national economy. The stability of the iron and steel production plays a vital “ballast stone” and “stabilizer” role for the upstream and downstream industry chain and even the entire industrial manufacturing industry.

In the face of the epidemic, Baosteel adheres to the principle of “not stopping production and not retreating”. In the face of the epidemic, Baosteel immediately established an emergency management leading group with the Party Secretary, chairman and general manager as the leaders and the deputy Party secretary as the executive deputy leaders, living together with the staff. All responsible persons of relevant units shall be on duty 24 hours under the state of on-site containment management.

Under the unified leadership of the general headquarters, the company divided each area into minimum units and established production protection teams according to the principle of “dividing small units and reducing cross”. Protect the implementation of “two classes” special production team 24 hours unattended mode of production, the implementation of grid closed management, fine clear staff activity area, walking paths, succession process, disposal of control requirements, such as abnormal production to increase efforts to control the key link, area, effectively avoid the flow of people between different grid area, build each line of defense.

In this major test of the epidemic, Baosteel intelligent manufacturing achievements for the anti-epidemic protection of production double front escort. The accumulation of digital, unmanned and intelligent achievements and the support of excellent professional teams have transformed the powerful potential energy of the application of digital intelligence technology into a new driving force for improving the level of scientific and precise prevention and control and improving the labor efficiency of production.

The wide application of digital, unmanned and remote intelligent manufacturing equipment, especially industrial robots, has achieved an effective balance between epidemic prevention and control and stable and high yield in a special period.

In Baosteel, there are only two workers on the 200-meter long production line for inspection. Several employees are scattered in the operation room of more than 100 square meters to remotely control the system. Unmanned cranes can transfer and transport 100,000 tons of finished steel coils every day. Bof one-key steelmaking, “black lamp factory”, intelligent unmanned warehouse, the world’s first unmanned molten iron transportation system…… The intelligent manufacturing equipment covering the whole plant has achieved an effective balance between epidemic prevention and control and stable and high yield during special periods. The reporter learned that baosteel’s industrial robot application has reached 920 sets, and will be doubled in 2022. The robot application direction has also expanded from the traditional multi-axis physical form to the field of process automation, and the application scenarios are becoming broader and broader. These fearless sealing and control, immune to the virus “super staff”, struggling in handling, labeling, bundling, loading, sampling, detection and other processes, to build a beautiful intelligent manufacturing “landscape”.

It is worth mentioning that, in order to strengthen the precise management and control of personnel in the whole field during closed production, Baosteel designed, developed and launched the grid personnel management App within one week before establishing the industry, supporting the precise management and control of more than 5,000 grids and 15,000 people in the whole field, and continuously updating and improving the system functions. It has successively added the functions of headquarters area pass code, antigen detection upload and automatic statistics of epidemic prevention data, recording more than 8,000 grids and nearly 20,000 pieces of site information in the factory every day, playing a strong role in technical support and data support for epidemic prevention and production stabilization in the factory.

In addition, Baosteel strategic product technical service team formed a “combat epidemic, protect services” party members commandos, the implementation of the team work “zero report” system. The technical service team stationed in Shanghai will connect with users on site in real time by digital and intelligent means to ensure that users can solve on-site problems without delay. Since March, Baosteel has completed 585 warranty contracts, with a total of nearly 50,000 tons of products allowed to be delivered to customers all over the country.

Post time: Apr-29-2022