Detail

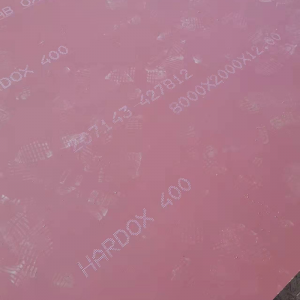

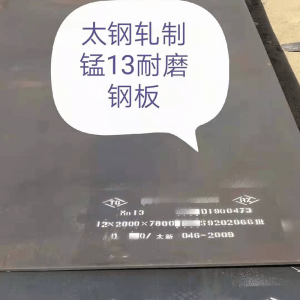

Main uses of imported wear-resisting steel plate:

1) Construction machinery and equipment: loader bulldozer excavator bucket plate, side blade plate, bucket bottom plate, blade, plate.

2) Loading and unloading machinery and equipment: unloading mill chain plate, hopper lining plate, grab blade plate, medium-sized automatic dump truck tipping plate

3) Construction machinery and equipment: cement pusher tooth plate, concrete mixer lining plate, mixing floor lining plate, dust collector lining plate

4) Metallurgical machinery and equipment: iron ore sintering conveying elbow, iron ore sintering machine lining plate, scraper machine lining plate

5) Mining machinery and equipment: lining plate of mining machinery.

6) Other mechanical equipment: sand mill barrel, blade, various wear-resistant parts of port machinery

7) Thermal power equipment: coal mill lining board, coal scutcher, coal delivery pipe, coal distributor plate, coal unloading equipment lining board

8) Shot blasting mechanical equipment: lining plate of shot blasting machine

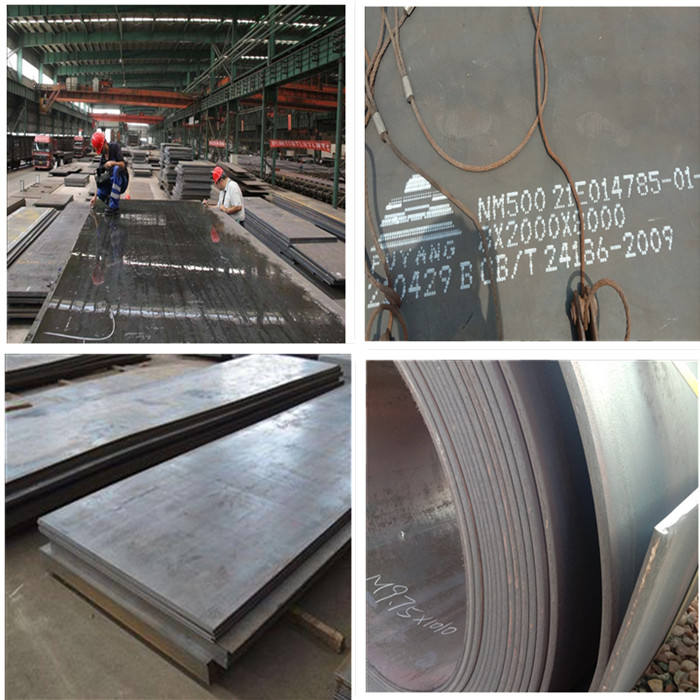

Since its establishment, the company has been to the quality of products as the fundamental survival of the enterprise, the quality of service as a bridge to our success we sincerely hope to establish business relations with our customers, to provide quality service, with entrepreneurship, common development.

Through continuous improvement, innovation, so that the quality level of our products to maintain in the forefront of the domestic industry.

Quality target: 98% of products pass the first delivery inspection, 0.2% of above products pass the first delivery inspection increase year by year, 100% of products pass the factory.

"Integrity, truth-seeking, development, innovation" is our company's business purpose for many years, warmly welcome the majority of stainless steel users and colleagues to visit our company, for the cause of wear plate create brilliant.

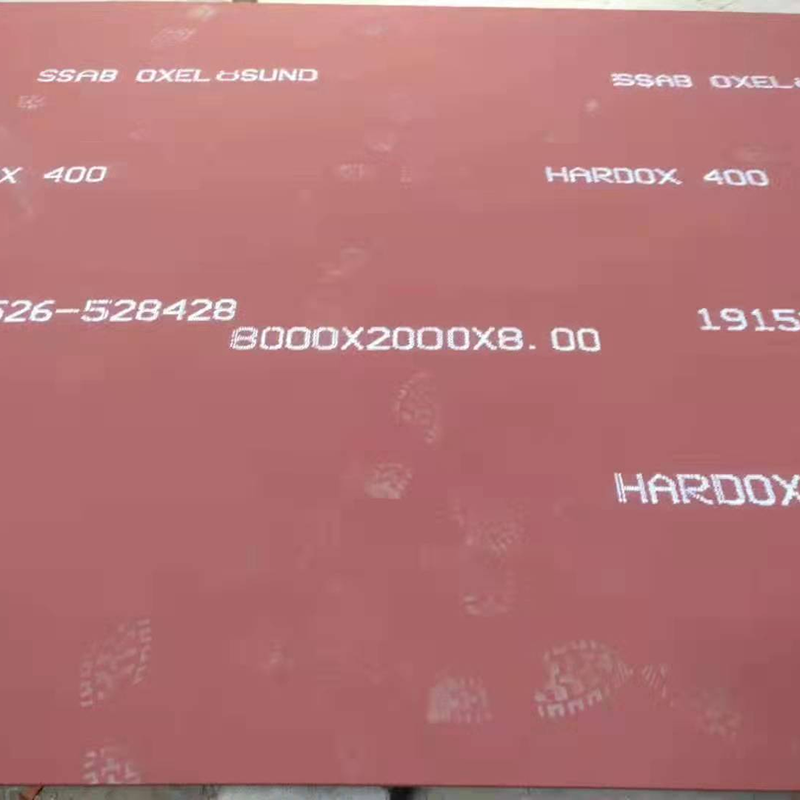

Wear-resistant steel plate

|

Grade |

NM360/NM400/NM450/NM500/RAEX400/RAEX450/RAEX500/NM360,BHNM400,BHNM450,BHNM500,BHNM550,BHNM600,BHNM650,NR360,NR400,B-HARD360, B-HARD400 |

|

Thickness |

3+3,4+4,5+5,6+4,6+5,6+6,8+4,8+5,8+6,8+7,8+8,10+4,10+5,10+6,10+7,10+8,10+9,10+10,10+20,12+4,12+5,12+6,12+7,12+8,12+9,12+1,12+11,12+12, 12+17,14+6,14+8,14+10,16+6,16+8,16+10,18+6,18+8,18+10,20+5,20+6,20+8,20+10,20+20,30+10,40+10, customized |

|

Width |

1500/2000/2500/3000MM |

More Products

1. Excellent wear resistance The chemical composition of the alloy wear-resistant layer has a carbon content of 4 to 5% and a chromium content of 25 to 30%. The volume fraction of Cr7C3 carbides in the metallographic structure is more than 50%. The macroscopic hardness is HRC56 to 62. The hardness is HV1400~1800. Because carbides are distributed perpendicularly in the direction of wear, even when compared with cast alloys of the same composition and hardness, the wear resistance is more than doubled. The comparison with the wear resistance of several typical materials is as follows: (1) With low carbon steel; 20~25:1 (2) With as-cast high chromium cast iron; 1.5~2.5:1

2. Good impact resistance The base plate of the wear-resistant composite steel plate is low carbon steel or low alloy. Tough materials such as stainless steel reflect the superiority of bimetal. The wear-resistant layer resists the wear of the wear medium, and the substrate bears the load of the medium, so it has good impact resistance. It can withstand the impact and wear of the high drop hopper in the material conveying system.

3. Good heat resistance The alloy wear-resistant layer is recommended to be used under ≤600℃. If vanadium, molybdenum and other alloys are added to the alloy wear-resistant layer, it can withstand high temperature wear of ≤800℃. The recommended operating temperature is as follows: Ordinary carbon steel base plate is recommended to be used under the working condition of not higher than 380℃; Low-alloy heat-resistant steel plate (15CrMo, 12Cr1MOV, etc.) substrates are recommended to be used in working conditions not higher than 540℃; The heat-resistant stainless steel substrate is recommended to be used at no higher than 800°C.

4. Good corrosion resistance The alloy layer of the wear-resistant composite steel plate contains a high percentage of metallic chromium, so it has a certain degree of rust and corrosion resistance. It can be used to prevent coal sticking when used in coal dropping drums and hoppers.

5. Complete varieties and specifications The wear-resistant steel plate has complete specifications and many varieties, and has become a commercial serialization. The thickness of the wear-resistant alloy layer is 3-20mm. The thickness of the composite steel plate is at least 6mm, and the thickness is not limited. The standard wear-resistant steel plate can be provided with 1200 or 3800×12000mm, and it can also be processed according to the size of the drawings according to user needs. Wear-resistant steel plates are now divided into three types: ordinary type, impact-resistant type and high-temperature type. Ordering high-temperature wear-resistant and impact-resistant composite steel plates should be explained.

6. Convenient processing performance The wear-resistant steel plate can be cut, bent or crimped, welded and punched, and it can be processed into various parts that can be processed by ordinary steel plates. The cut wear-resistant steel plates can be tailor-welded into various engineering structural parts or parts.

7. Functions and Features It can be welded and has good wear resistance..